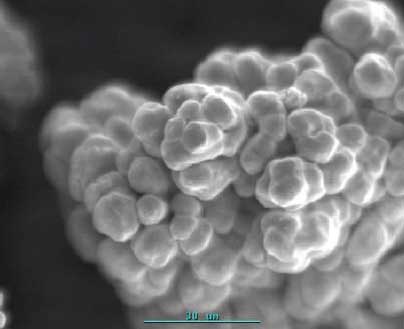

Silver powder at the highest purity and different properties is used in many applications: In production of silver-contained contact materials, carbon brushes, diamond tools, on the growth markets of the wind and solar industry, as a basis for, e.g., ECG- / EEG electrodes in the medical technology and in innovative applications such as antibacterial coatings. Silver powder is also used for conductive preparations such as pastes, varnishes and glues in electrical engineering and electronics.

DODUCO closely cooperates with the customers to develop special silver powder for demanding applications and has a broad range of different production procedures in order to meet these requirements.

DODUCO also offers silver-plating of various copper powders. This surface treatment permits elementary improvement of the properties of the basic material of copper, in particular corrosion resilience, electrical conductivity and soldering capacity of the material.

The possible uses of the powder are determined by factors such as grain size, grain shape, bulk density and silver content. Of course, the powders named below are only examples. Specific powders can be implemented according to the customer’s requirements.

Coarse powders have diverse uses in the production of carbon brushes.

Finer, electrolytic powders, in contrast, are found rather in electrically conductive silicones, plastics, varnishes, paints and pastes that can be used, among others, for electromagnetic shielding.

Thus, refined copper powders not only offer the option of substituting pure copper to improve the product properties, but may also permit an additional more cost-efficient alternative for pure silver powder, depending on application.

DODUCO’s precious metal refinery, which currently has an output of up to 500 metric tons per year, counts among the leading silver refineries in Europe. With broad experience and know-how DODUCO offers silver to customers and traders as investments and raw material. Fully recycled, 99.99% pure fine silver is available in different sizes of bars as well as in granules or wire blanks.

Due to increasing demand for silver alongside limited natural resources, “urban mining” is of particular importance. DODUCO’s goal is to satisfy the needs of the market with high-quality recycled silver coming from jewelry and industrial production scrap. Through consistent research and development, DODUCO has continually increased process efficiency. For 100 years, DODUCO has always prioritized its responsibility to the environment. As a symbol of environmental commitment, DODUCO has received all of the necessary industry certifications and approvals. All fine silver used for products, silver-powders or bars placed on the market by DODUCO is recovered by in-house recycling processes. There is an explicit guarantee that no mined silver has been used in these products.

DODUCO is proud to actively contribute to sustainable secondary recovery.

DODUCO also supplies high-purity fine silver in the form of wire blanks – perfectly suited for your anode baskets. The blanks are approximately 10 x 15 mm in size and have an outstandingly uniform structure. Of particular interest is the high level of purity of the silver – 99.99% – which guarantees an extremely low carry-over of contamination in the electroplating bath and a perfect finish. The standard packaging unit of 10 kg in tearproof plastic sacks is also practical and in line with occupational safety concerns. The wire blanks are available from stock at short notice.

DODUCO is a reliable, LBMA certified German manufacturer of silver salts (silver cyanide and potassium silver cyanide) as well as other precious-metal-containing slats and solutions with nearly a century of experience.

Silver salts are used often in galvanotechnical processes and galvanochemicals or galvanic baths. DODUCO supplies the products listed here to commercial purchasers, such as galvanisation plants, only, but not to private end consumers.

Precious metal salts by DODUCO are characterized by highest purity and a particularly good pourability.

Resource-protecting and conflict-free

Within the Saxonia-Group also gold salts are offered at Wieland Edelmetalle in Pforzheim.

The fine gold used for production of such salts is guaranteed to come from conflict-free origins.

With 100 years of experience, DODUCO is a reliable, LBMA-certified German manufacturer of precious-metal-containing products. One of its product categories are precious-metal-containing conductive preparations (silver-pigmented) and precious-metal-free conductive preparations (graphite-pigmented), such as varnishes and pastes.

The silver content in silver-pigmented conductive preparations is produced in DODUCO-specific processes as silver powder or silver flakes.

Depending on composition of the conductive preparation, the resulting properties and the technical requirements, these products are often used in many different electrical and electronic areas where conductive layers are needed.

DODUCO precious metal preparations and graphite preparations are characterized by higher purity, particularly good homogeneity and long-term stability (durability).

DODUCO’s silver-pigmented conductive varnishes are liquid, solvent-containing, physically drying varnishes. Depending on the area of application (carrier material, drying requirements), there are mostly two types distinguished:

At a silver share of approx. 40 % silver (exceptions are possible) in the form of silver powder or silver flakes from own production, DODUCO’s silver conductive varnishes are characterized by high electrical conductivities at low viscosities. The liquid conductive varnishes can be applied to the carrier materials by brush, roller or submersion. If a spray application is desired, the conductive varnish should be mixed with the corresponding diluent (information on the diluent is available on request). Drying takes place by evaporation of the solvents contained in the temperature range between 20-100°C (on demand, higher temperatures are possible as well).

The benefit of the silver conductive varnishes as compared to the pastes is in simple processing and quick drying. Furthermore, they have a strong, good adhesion to the base and very good electrical and thermal conductivity.

The also physically drying silver-pigmented conductive pastes of DODUCO’s range have a much higher viscosity than the conductive varnishes. This is caused by higher shares of silver (approx. 60%) and use of polymer basic components for formation of polymer compounds / design of the polymer structure. The silver used in the silver conductive pastes in the form of silver powder or silver flakes is also from the DODUCO-internal production.

The silver-pigmented polymer thick-film pastes are characterized by good electrical and thermal conductivity as well as good adhesion and bending resistance while being highly flexible. The application of conductive pastes preferably takes place by screen printing, with selection of the mesh size varying depending on printing pattern, layer thickness and base. Drying and curing may take place in circulation air dryers, IR-dryers or special tunnel furnaces.

On remand, the silver-pigmented conductive pastes can also be adjusted to different processing techniques (e.g. pad printing). The chemicals required for this may be purchased from DODUCO on request.

The benefit of silver conductive pastes as compared to the varnishes is in the better adhesion to plastic bases as well as films. I spite of high demands by increased flexibility, the layers remain stable and retain their very good conductivity.

Similar to silver-pigmented conductive preparations, precious-metal-free, graphite-pigmented conductive preparations are also based on decades of experience in production. The close cooperation with the customer has enabled DODUCO as producer to develop a selection of precious-metal-free conductive preparations that cover a broad area of use.

Packaging sizes of 1 kg product per unit have proven their worth for practical use. The diluents can be delivered in different amounts as well depending on your needs and upon request.

Both DODUCO’s graphite conductive varnishes and graphite conductive pastes are sold under the brand name of GRAPHAROL®. Both product groups are made conductive by the addition of a special graphite pigment. Thus, the product will often have enough conductivity and offer a cost-efficient alternative for precious-metal-containing products. However, if you have any greater requirements to the conductive layer, you should use a silver-containing conductive product.

Similar to the silver conductive preparations, graphite conductive preparations adhere well to many plastics and other carrier materials. The solvents contained permit quick drying even at low temperatures and simple processing.

The thinly liquid graphite conductive varnishes are usually applied by spraying or with a brush. More viscose graphite conductive pastes are recommended for screen printing. Additional of a suitable diluent (information available on request) permits variation of the viscosities as required.

Depending on the area of application (carrier material, drying requirements), there are mostly two types distinguished:

DODUCO has developed its experience and expertise in manufacturing of ECG and EEG electrodes for the medical technology over the past decades.

It is based on the in-house manufacturing of proprietary silver/silver chloride powders used in a variety of special blends. This material is the well proven base material of choice for ECG and EEG electrodes.

DODUCO manufactures electrodes in different diameters and thicknesses with and without silver pins already incorporated. Both, the material blend composition and the dimensions are mostly specified by our customers and can be customized to meet their specific requirements.

DODUCO produces these electrodes in pill or disc form, allowing our customers to further integrate them into their design during manufacturing into their end product.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from YouTube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Facebook. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from Instagram. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationYou are currently viewing a placeholder content from X. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information